The electronics industry moves fast. One delayed shipment of defective plastic housings can halt an entire production line, costing thousands per hour. If you’re sourcing components for smartphones, laptops, or smart home devices, you already know that finding a reliable injection molding machine distributor isn’t just about price—it’s about precision, consistency, and speed. The wrong partner can leave you scrambling with rejected parts and missed deadlines.

But here’s the problem: many distributors promise quality machines, then disappear when you need technical support or replacement parts. You’re left troubleshooting machine failures with no backup. That’s where working directly with a manufacturer changes everything. At Daoben Machinery, we manufacture injection molding machines from 30 tons to 4000 tons, eliminating middleman delays and giving you direct access to engineering expertise. Whether you’re molding micro-connectors or large enclosures, the right equipment paired with the right support can transform your production efficiency.

Table of Contents

Toggle- Why the Electronics Industry Needs Specialized Injection Molding Solutions

- Choosing the Right Tonnage for Electronics Components

- Key Features to Demand from Your Plastic Molding Machine Partner

- Material Compatibility: Engineering Resins for Electronics

- Precision Mold Design Considerations for Electronics

- Automation Integration for High-Volume Electronics Production

- Quality Control Standards for Electronics Manufacturing

- Energy Efficiency and Sustainability in Modern Molding Equipment

- Maintenance and Longevity: Protecting Your Investment

- Cost Analysis: Total Ownership Beyond Purchase Price

- Working Directly with Manufacturers vs. Multi-Layer Distribution

- Industry 4.0 Integration and Smart Factory Connectivity

- Regional Considerations and Global Supply Chains

- Making the Final Decision: Evaluation Checklist

- Start Your Electronics Manufacturing Journey with Daoben Machinery

Why the Electronics Industry Needs Specialized Injection Molding Solutions

Electronics manufacturing demands precision that most industries never encounter. We’re talking tolerances measured in microns, not millimeters. A smartphone casing needs to fit perfectly over delicate circuit boards. A laptop hinge requires exact dimensions to function smoothly over thousands of open-close cycles. USB ports, battery compartments, and cable connectors all depend on injection-molded plastics that meet strict specifications.

Standard plastic molding machines often fall short for electronics work. You need machines with advanced temperature control to handle engineering-grade resins like PC/ABS blends, nylon, and glass-filled polymers. You need fast cycle times because electronics production runs operate on tight schedules. And you absolutely need repeatability—when you’re producing 50,000 identical parts, variation is your enemy.

Working with an experienced injection molding machine distributor who understands electronics manufacturing makes all the difference. They know which machine tonnage suits your part size. They understand cavity configurations for multi-component assemblies. They can recommend auxiliary equipment like robotic arms for insert molding or hot runner systems for zero-waste production.

Electronics manufacturers also face unique material challenges. Many components require flame-retardant plastics that meet UL94 standards. Some need static-dissipative resins to protect sensitive circuits. Others demand optical-grade clarity for LED lenses or display bezels. Your molding equipment must handle these specialty materials without degradation or contamination.

Choosing the Right Tonnage for Electronics Components

Tonnage selection sounds technical, but it’s actually straightforward once you understand the basics. The tonnage of an injection molding machine refers to the clamping force—how tightly the machine holds the mold shut during injection. Too little force, and molten plastic leaks out (called “flashing”). Too much force, and you risk damaging precision molds.

For most electronics components, you’ll work in the 50-ton to 300-ton range. Small connectors and buttons might only need 30-50 tons. Mid-sized housings for routers or power adapters typically require 80-150 tons. Larger items like printer covers or monitor frames might push into 200-300 ton territory.

Here’s a simple calculation: multiply your part’s projected area (in square inches) by the material’s recommended pressure (usually 2-8 tons per square inch). A smartphone back cover measuring 6 inches by 3 inches has 18 square inches of projected area. Using ABS at 5 tons per square inch, you’d need roughly 90 tons of clamping force. Always add a 20% buffer for safety.

But tonnage isn’t everything. Shot size matters too. This measures how much molten plastic the machine can inject in one cycle. A 150-ton machine might have a shot size of 5 ounces or 15 ounces depending on the screw diameter. Match your part weight to the machine’s optimal shot size range (typically 20-80% of maximum capacity) for best results.

Key Features to Demand from Your Plastic Molding Machine Partner

Not all distributors operate the same way. Some simply move boxes from warehouse to customer. Others provide genuine value through technical expertise and after-sales support. When evaluating potential partners for your plastic molding machine needs, look for these non-negotiable features:

Direct manufacturer relationships. The best distributors work directly with factories, not through multiple intermediaries. This shortens lead times, reduces costs, and ensures they actually understand the equipment. At Daoben Machinery, we are the manufacturer, which means you’re getting equipment information straight from the engineers who designed it.

Technical training programs. New equipment means nothing if your operators don’t know how to use it properly. Your distributor should offer comprehensive training—both initial setup and ongoing education. This includes proper material handling, preventive maintenance schedules, and troubleshooting common issues.

Spare parts availability. Here’s a nightmare scenario: your machine breaks down, and the part you need has a 12-week lead time from overseas. A quality distributor maintains local inventory of critical spare parts. They should also provide clear parts diagrams and ordering systems so you can stock your own emergency inventory.

Process optimization support. Buying a machine is just the start. Getting consistent quality from that machine requires process refinement. Your distributor should help you dial in optimal temperatures, pressures, and cycle times for your specific materials and part designs. Some offer on-site process audits to identify efficiency improvements.

For electronics manufacturers specifically, look for distributors who understand cleanroom requirements. Many electronic components need to be molded in controlled environments to prevent contamination. Your equipment should support this, with features like enclosed hoppers, filtered hydraulic systems, and low-particulate designs. You can explore more about specialized molding solutions to understand how equipment adapts to different manufacturing environments.

Material Compatibility: Engineering Resins for Electronics

Walk into any electronics factory, and you’ll encounter materials you’ve never heard of. These aren’t your everyday plastics. Electronics-grade resins have specific properties that standard materials can’t match. Your injection molding machine needs to handle them without issues.

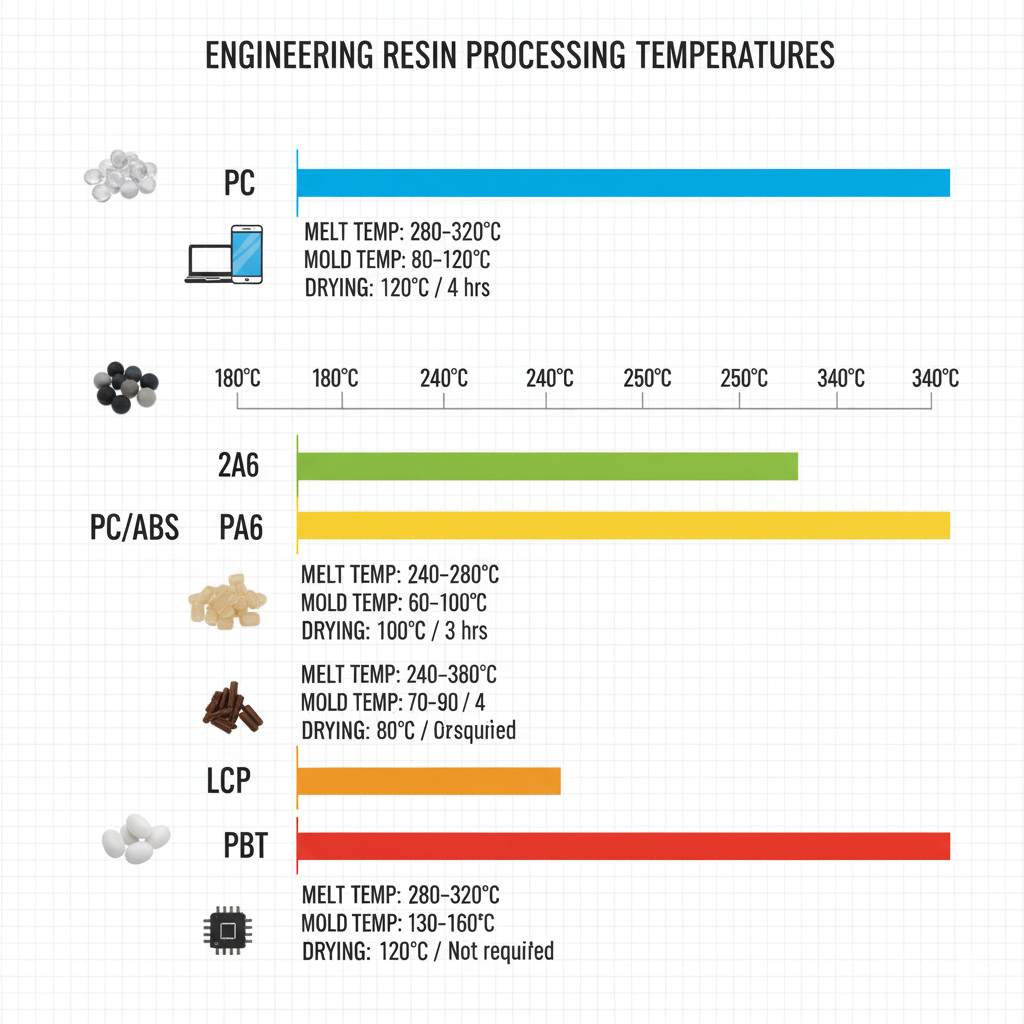

Polycarbonate (PC) dominates in applications requiring impact resistance and optical clarity. Phone screens, laptop bezels, and LED lenses all use PC. But PC processes at high temperatures (270-320°C), which demands excellent barrel temperature control and wear-resistant screws.

PC/ABS blends offer the best of both worlds—polycarbonate’s toughness with ABS’s easy processing. You’ll find this material in laptop housings, printer covers, and power tool shells. It flows well and produces good surface finishes, making it popular for visible components.

Nylon (PA) suits structural parts that bear mechanical stress. Cable connectors, mounting brackets, and gear assemblies often use nylon due to its strength and wear resistance. Glass-filled nylon variants add stiffness for applications like automotive electronics. However, nylon is hygroscopic—it absorbs moisture—so proper drying before molding is critical.

Liquid Crystal Polymer (LCP) represents the high end of electronics materials. Its incredibly tight tolerances and excellent dimensional stability make it ideal for precision connectors and antenna components. LCP also handles high frequencies well, important for 5G and wireless devices. Processing LCP requires machines with precise injection control and minimal residence time to prevent degradation.

Flame-retardant grades of most plastics meet UL94 V-0 ratings required for consumer electronics. These formulations contain additives that prevent flame spread, essential for safety certifications. Your molding equipment must maintain consistent processing conditions because flame retardants can be temperature-sensitive.

Understanding plastic injection molding processes helps clarify why material selection impacts equipment requirements. Different polymers need different screw designs, barrel configurations, and control systems.

Precision Mold Design Considerations for Electronics

The machine is only half the equation. Your mold design determines final part quality just as much as the equipment running it. Electronics components demand molds built to exacting standards, often with features you won’t find in general-purpose tooling.

Multi-cavity layouts maximize production efficiency. Instead of molding one phone case per cycle, a multi-cavity mold produces 4, 8, or even 16 identical parts simultaneously. But this requires exceptional balance—each cavity must fill at exactly the same rate and pressure. An experienced injection molding machine distributor can recommend equipment with the precise control needed for balanced multi-cavity production.

Hot runner systems eliminate the waste associated with traditional cold runners. In high-volume electronics manufacturing, material cost matters. Hot runners keep plastic molten in the distribution channels, so you only pay for the plastic in the actual parts. They also reduce cycle times by eliminating the need to cool and eject runner material. However, hot runners add complexity and require machines with sophisticated temperature control zones.

Insert molding capabilities allow you to mold plastic around pre-placed metal components. Many electronics parts combine metal inserts (for threading, electrical contacts, or structural reinforcement) with plastic housings. Your machine needs precise positioning control and gentle injection pressure to avoid displacing inserts during the molding process.

Micro-molding features handle the tiny details electronics demand. Consider a USB-C connector housing—the tongue that goes into the port measures just 2.5mm wide with precise internal dimensions. Producing such features requires machines with ultra-precise injection control, minimal shot-to-shot variation, and excellent repeatability. Some manufacturers use all-electric machines for this level of precision.

Surface finish requirements in electronics are often non-negotiable. Glossy finishes need perfectly polished mold surfaces. Textured finishes require EDM texturing that maintains dimension. And optical components demand mold surfaces with Ra values under 0.05 microns. Your mold builder and machine supplier need to work together to achieve these results consistently.

When you’re evaluating options, understanding comprehensive price factors helps you budget appropriately for both equipment and tooling. The machine cost is just one piece of your total investment.

Automation Integration for High-Volume Electronics Production

Electronics manufacturing runs on volume. A single smartphone model might require 10 million units in its first year. At that scale, manual operation becomes impossible. Automation transforms your injection molding machine from a standalone tool into part of an integrated production system.

Robotic part removal is the most common automation. A robot arm reaches into the mold, grabs the finished parts, and places them on a conveyor or into a tote. This happens in seconds, often while the machine prepares the next shot. Robots never tire, never miss a part, and never damage delicate components through rough handling. For electronics, you might use vacuum grippers or custom end-effectors designed for your specific part geometry.

Vision inspection systems catch defects immediately. A camera captures images of each molded part as the robot removes it. Machine learning algorithms analyze the images in real-time, checking for short shots, flash, discoloration, or dimensional issues. Defective parts get automatically sorted into a reject bin. This level of quality control is essential when you’re shipping parts to electronics assembly lines that operate with near-zero defect tolerance.

In-mold decorating (IMD) and in-mold labeling (IML) add graphics during the molding process itself. The robot places a pre-printed film into the mold before injection. The molten plastic fuses with the film, creating a permanent decorative or functional surface. This eliminates secondary operations like pad printing or hot stamping. You’ll see IMD on everything from appliance control panels to automotive dashboard components.

Material handling automation extends beyond the machine itself. Automated dryers ensure material reaches optimal moisture content. Vacuum conveying systems move resin from storage hoppers to machine hoppers without manual intervention. Color dosing systems automatically blend virgin resin with colorant pellets at precise ratios. All of this reduces labor while improving consistency.

The key is choosing a machine designed for automation from the start. Look for features like standardized robot mounting plates, programmable I/O interfaces for peripheral equipment, and control systems that can communicate via standard protocols (Ethernet/IP, Modbus, OPC-UA). Companies that manufacture large-tonnage equipment often build automation-ready features into their designs because their customers demand it.

Quality Control Standards for Electronics Manufacturing

Electronics manufacturers face stricter quality requirements than almost any other industry. Your customers expect every part to meet specification, every time. A single defective housing that allows moisture ingress can destroy an entire device. That’s why quality control starts with your molding process, not with final inspection.

Statistical Process Control (SPC) monitors machine performance in real-time. Modern machines track dozens of parameters for every shot—injection pressure, screw position, melt temperature, cooling time, and more. SPC software analyzes this data to detect trends before they become problems. If cycle time starts creeping upward, that might indicate material degradation or a cooling system issue. Catching it early prevents scrapped parts.

First Article Inspection (FAI) validates new production runs. When you start a new job or change materials, the first parts off the machine get comprehensive measurement. This includes dimensional checks with CMM (Coordinate Measuring Machine) equipment, weight verification, visual inspection under magnification, and functional testing if applicable. Only after FAI approval does full production begin.

In-process monitoring happens continuously during production. Cavity pressure sensors inside the mold track how plastic fills each cavity. This reveals issues like short shots or flashing before they produce visible defects. Some manufacturers use ultrasonic sensors to verify wall thickness without cutting parts open. Others employ infrared cameras to monitor cooling patterns and detect hot spots.

Material certification ensures you’re molding with the right resin. Every material lot should come with a Certificate of Conformance listing properties like melt flow index, tensile strength, and flame rating. Smart factories scan these certificates into their quality management systems and link them to specific production lots. If a quality issue emerges months later, you can trace it back to the exact material batch used.

Environmental testing validates parts for real-world conditions. Electronics often face temperature extremes, humidity, vibration, and chemical exposure. Your molded components need to survive all of it. Accelerated aging tests expose parts to high temperatures for extended periods. Salt spray tests check corrosion resistance. Drop tests verify impact strength. These tests should happen during product development, but periodic re-validation ensures ongoing quality.

Major electronics brands audit their suppliers regularly. They want to see documented quality systems, calibrated measurement equipment, trained operators, and continuous improvement programs. Working with reputable equipment manufacturers helps you meet these expectations. When buyers evaluate top machine brands, they’re looking for suppliers who understand these quality requirements.

Energy Efficiency and Sustainability in Modern Molding Equipment

Energy costs hit electronics manufacturers hard. When you’re running machines 24/7, every watt matters. Modern injection molding machines offer dramatically better energy efficiency than older hydraulic models, potentially cutting power consumption by 50-70%.

All-electric machines lead in efficiency. They use servo motors to drive every function—injection, clamping, ejection. Motors only consume power when actually moving, unlike hydraulic pumps that run continuously. For a 150-ton machine, this might mean reducing power consumption from 30-40 kW down to 10-15 kW during typical operation. Over a year of three-shift operation, that’s substantial savings.

Hybrid machines combine hydraulic clamping with electric injection and control. They offer better efficiency than pure hydraulic machines while costing less than all-electric models. The electric injection unit provides the precision electronics manufacturing demands, while hydraulic clamping delivers the force needed for larger parts. Many electronics manufacturers find hybrids offer the best balance of performance, efficiency, and cost.

Variable speed pumps improve hydraulic machine efficiency. Instead of running at constant speed regardless of demand, variable speed drives adjust pump speed to match what the machine actually needs at each moment. This cuts energy waste significantly compared to fixed-speed pumps that dump excess flow through relief valves as heat.

Optimized heating systems reduce thermal energy consumption. Modern barrel heaters use ceramic band heaters with better insulation and more even heat distribution. Some machines employ induction heating in critical zones for faster response and tighter temperature control. Properly sized heaters prevent the constant on-off cycling that wastes energy.

Heat recovery systems capture waste heat for productive use. The cooling system removes heat from molds and hydraulic oil. Instead of dumping this heat to atmosphere, some manufacturers route it to preheat plastic material or warm facility spaces in winter. Every BTU you can reuse is energy you don’t have to pay for twice.

Sustainability matters beyond energy costs. Electronics brands face increasing pressure to reduce environmental impact. Many now require suppliers to report energy consumption, material waste, and carbon footprint. Choosing efficient equipment helps you meet these requirements while cutting operating costs. Facilities that also produce other products like plastic chairs or buckets can often share infrastructure and further optimize resource use across product lines.

Maintenance and Longevity: Protecting Your Investment

A quality plastic molding machine represents a significant capital investment—anywhere from $50,000 for smaller machines to $500,000+ for large-tonnage models with full automation. Protecting that investment requires proper maintenance. Neglect leads to costly breakdowns, inconsistent quality, and shortened equipment life.

Preventive maintenance schedules keep machines running smoothly. This includes daily tasks (checking oil levels, inspecting safety systems), weekly routines (cleaning mold areas, lubricating moving parts), and monthly procedures (filter changes, alignment checks). The machine manufacturer provides detailed maintenance schedules—follow them religiously.

Wear part replacement happens on predictable intervals. Screws and barrels wear from processing abrasive materials or corrosive additives. Check rings, non-return valves, and nozzle tips need periodic replacement. Hydraulic seals dry out over time. Rather than waiting for failure, plan replacements based on machine hours or shot count. This prevents catastrophic failures that halt production.

Hydraulic system care is critical for hydraulic and hybrid machines. Hydraulic oil degrades over time, losing viscosity and accumulating contamination. Change oil according to manufacturer recommendations—typically annually or after 2,000-3,000 operating hours. Use the specified oil type; substituting cheaper alternatives can damage pumps and valves. Keep the system clean by regularly replacing filters and checking for leaks.

Control system updates extend machine life. Electronics advance rapidly. A machine’s control system from 2015 might seem outdated compared to 2025 technology, but it’s still functional. However, manufacturers often release software updates that improve performance, add features, or fix bugs. Installing these updates keeps your machine current without requiring complete replacement.

Operator training reduces damage from user error. Many machine problems stem from improper operation rather than mechanical failure. Operators who understand proper startup/shutdown procedures, material handling protocols, and basic troubleshooting prevent most issues. Invest in training—both initial and refresher courses.

Documentation systems track machine history. Maintain logs of all maintenance performed, parts replaced, and issues encountered. Modern factories use computerized maintenance management systems (CMMS) to schedule tasks, track costs, and analyze failure patterns. This data becomes invaluable when diagnosing recurring problems or planning major repairs.

When working with an injection molding machine distributor, ask about their service capabilities. Can they provide emergency repairs? Do they stock common spare parts locally? Can they offer remote troubleshooting to minimize downtime? These services become crucial when production stops unexpectedly.

Cost Analysis: Total Ownership Beyond Purchase Price

That sticker price on an injection molding machine tells only part of the story. Smart buyers calculate total cost of ownership (TCO) over the machine’s expected 15-20 year lifespan. TCO includes the purchase price plus all operating costs minus the residual value when you eventually retire the equipment.

Initial investment breaks into several components. The machine itself is obvious, but don’t forget installation (electrical work, water connections, compressed air), auxiliary equipment (chillers, dryers, material handling), tooling costs, and training. For a complete turnkey cell, these additions might equal 40-60% of the base machine price.

Energy costs we covered earlier, but they deserve emphasis. An inefficient machine might consume $30,000 more energy annually than an efficient model. Over 15 years, that’s $450,000—potentially more than the machine’s purchase price. When comparing options, calculate the payback period on higher-efficiency equipment. Often it’s under 3 years.

Maintenance and repairs vary by machine type and build quality. Budget roughly 2-4% of machine value annually for routine maintenance on well-built equipment. Add another 1-2% for unexpected repairs. Cheaper machines often cost more to maintain because parts fail more frequently and may be harder to source.

Labor costs depend on automation level. A manual machine requires an operator’s constant attention. An automated cell with proper monitoring might need one operator per 3-4 machines. If your labor rate is $25/hour including benefits, that’s $50,000+ per year per full-time operator. Automation pays for itself quickly in high-wage regions.

Material efficiency affects operating costs significantly. Machines with tight process control reduce scrap rates. Hot runner systems eliminate runner waste. Proper material drying prevents moisture-related defects. A 2% improvement in yield might save $10,000-$50,000 annually depending on material costs and production volume.

Downtime costs can dwarf other expenses. If your machine failure halts an assembly line that produces $1,000 of value per hour, a 4-hour breakdown costs $4,000 in lost production plus rush freight for alternative supplies plus customer penalties for late delivery. Reliable equipment with good service support prevents these disasters.

Residual value recovers some of your investment. Well-maintained machines from reputable manufacturers hold value. You might recover 20-30% of original cost after 15 years. Machines from unknown brands or with poor maintenance records become worthless, suitable only for scrap metal value.

Run these numbers for any equipment purchase. A machine that costs 10% more upfront but delivers 20% better energy efficiency and 50% lower maintenance costs will save money over its lifetime. This analysis often reveals that buying from a direct manufacturer like Daoben Machinery, rather than through multiple distributor layers, offers better TCO through lower initial cost and superior support.

Working Directly with Manufacturers vs. Multi-Layer Distribution

Here’s a question that affects everything: should you buy from a local distributor or go directly to the manufacturer? Both models exist for good reasons, but they serve different needs. Understanding the tradeoffs helps you make the right choice for your situation.

Local distributors offer proximity and convenience. They maintain demo equipment you can test. They stock spare parts for immediate delivery. Their service technicians can reach you within hours, not days. For many buyers, these benefits justify paying the distributor’s markup—typically 20-40% over manufacturer direct pricing.

Regional distributors cover larger territories and often represent multiple equipment brands. This breadth of selection helps when you’re not sure exactly what you need. They can recommend the best fit from their entire portfolio. However, their technical expertise may be shallow—they know a little about many machines rather than deep knowledge of one product line.

Direct manufacturer relationships eliminate middleman markups. You get equipment at factory pricing, which can mean significant savings on large orders. More importantly, you access the engineers who designed the machines. When you have a technical question, you’re talking to someone who actually understands the equipment at a fundamental level, not just someone reading from a manual.

Manufacturing expertise makes the biggest difference during critical moments. When you’re troubleshooting a mysterious defect or optimizing a challenging material, engineering support from the manufacturer can solve problems that stump local representatives. At Daoben Machinery, our engineers have designed machines for thousands of applications. That depth of experience is invaluable.

Communication efficiency improves when you eliminate layers. Instead of your request going from you to local distributor to regional office to manufacturer and back, you speak directly with the people who can help. This speeds problem resolution and ensures nothing gets lost in translation.

Customization capability increases with direct manufacturer access. Need a special barrel configuration for a unique material? Want integration with your facility’s MES system? Manufacturers can accommodate special requests that distributors typically cannot. Your machine gets configured exactly to your needs.

After-sales support quality varies by manufacturer. Some excel at customer service. Others treat support as an afterthought. Before committing, ask about their support structure. Do they have English-speaking technical support? What are their response times? Can they provide remote assistance? Do they maintain spare parts inventory in your region or country?

The best choice depends on your situation. If you’re buying one machine for a job shop and need extensive hand-holding, a local distributor might be worth the premium. But if you’re equipping a high-volume electronics facility with multiple machines, direct manufacturer relationships typically offer better value and support. The cost savings alone often exceed what you’d pay for a dedicated service contract with local providers.

Industry 4.0 Integration and Smart Factory Connectivity

Electronics manufacturers lead the charge toward smart factories. Your molding equipment needs to participate in this connected ecosystem, not operate as isolated islands. Modern injection molding machines support Industry 4.0 concepts that transform manufacturing efficiency.

Machine connectivity enables real-time monitoring. Each machine communicates operating status, production counts, quality metrics, and maintenance alerts to central systems. Plant managers view dashboards showing every machine’s current state. Production planners receive automatic notifications when jobs complete. Maintenance teams get alerted to developing issues before failures occur.

OEE tracking (Overall Equipment Effectiveness) quantifies machine performance. OEE combines availability (uptime vs. downtime), performance (actual vs. ideal cycle time), and quality (good parts vs. total parts). World-class manufacturers target OEE above 85%. Automated data collection from connected machines provides accurate OEE calculations without manual logging.

Predictive maintenance uses machine data to forecast failures. Sensors monitor vibration, temperature, pressure, and other parameters. Machine learning algorithms detect patterns that precede failures. A slight increase in hydraulic pressure variation might predict a pump bearing failure weeks in advance. This allows planned maintenance during scheduled downtime rather than emergency repairs during production runs.

Digital twin technology creates virtual replicas of physical machines. Engineers can simulate different operating scenarios, test process changes, or troubleshoot issues using the digital twin before touching the actual machine. This reduces trial-and-error experimentation and prevents downtime for testing.

Recipe management stores optimal process parameters for each product. When switching from one part to another, the operator selects the corresponding recipe, and the machine automatically adjusts all settings—temperatures, pressures, speeds, positions. This eliminates setup errors and reduces changeover time from hours to minutes.

Quality integration links molding data with inspection results. When a defect appears during inspection, the system automatically correlates it with the machine data from when that part was molded. This accelerates root cause analysis. Instead of wondering what changed, you have exact parameter values from the relevant cycle.

Supply chain connectivity extends beyond the factory floor. Your machine can communicate material consumption to inventory systems, triggering automatic reordering when supplies run low. Production completion signals shipping systems to prepare outbound logistics. This level of integration minimizes human intervention and prevents disruptions.

Not every manufacturer offers comprehensive Industry 4.0 capabilities. When evaluating suppliers, ask specific questions about data protocols, available APIs, and integration examples. The most forward-thinking manufacturers actively partner with MES and ERP vendors to ensure smooth connectivity.

Regional Considerations and Global Supply Chains

Electronics manufacturing is global. Your components might be molded in one country, assembled in another, and sold worldwide. This reality affects how you source molding equipment and structure your production network.

Equipment standardization across multiple facilities simplifies operations. If your company has plants in Asia, Europe, and North America, using the same machine models everywhere enables knowledge transfer between sites. Operators can move between facilities without retraining. Maintenance procedures stay consistent. Process parameters transfer directly. Your injection molding machine distributor should be able to support all your locations.

Local content requirements in some regions influence equipment sourcing. Various countries offer tax incentives or mandate local content percentages for manufactured goods. Understanding these regulations helps optimize your equipment procurement strategy. Sometimes splitting purchases between local and imported equipment makes sense.

Shipping and logistics for large machines require careful planning. A 300-ton machine weighs several tons and occupies significant space. Ocean freight takes 4-8 weeks from Asian manufacturers to Western markets. Air freight costs prohibitively for such heavy equipment. Factor these lead times into your project schedules.

Installation support matters when working across borders. Can your equipment supplier provide installation support in your country? Do they have partnerships with local rigging companies? Can they send technicians for commissioning, or will you rely on remote guidance? These details prevent surprises when your machine arrives.

Voltage and frequency differences require attention. North America uses 208/230/460V at 60Hz. Europe uses 400V at 50Hz. Asia varies by country. Ordering equipment with the wrong electrical specifications creates expensive problems. Reputable manufacturers configure machines for your local power supply before shipment.

Certification requirements vary by market. CE marking is mandatory for Europe. UL certification matters for North American safety compliance. Some countries require additional local certifications. Your equipment should arrive with all necessary compliance documentation. Don’t assume—verify certifications match your requirements before ordering.

Language and documentation affect daily operations. Control panels, instruction manuals, and troubleshooting guides should be available in languages your team speaks. Machine interfaces with poor translations frustrate operators and increase error rates. Quality manufacturers provide professional translations, not machine-generated text.

Time zone challenges complicate support when your equipment supplier is halfway around the world. An urgent technical question at 9 AM your time might be 9 PM their time. Look for manufacturers with support structures that provide reasonable response times despite time differences. Some maintain regional support centers for better coverage.

Currency fluctuations impact equipment costs when buying internationally. A machine priced at $100,000 might cost you 10% more or less six months later if exchange rates shift. Consider timing large purchases when currency rates are favorable, or negotiate fixed pricing in your local currency if the manufacturer agrees.

Import duties and taxes add to your total cost. Tariffs on injection molding machines vary by country of origin and destination. Some trade agreements reduce or eliminate duties. Your accounting team should calculate landed costs including all duties, taxes, freight, and clearing fees to compare options accurately.

Despite these complexities, global sourcing often provides better value than local-only options. Chinese manufacturers like Daoben Machinery offer competitive pricing due to efficient production scale, while still providing the technical sophistication that electronics manufacturing demands. The key is working with manufacturers who understand international business and support customers worldwide.

Making the Final Decision: Evaluation Checklist

You’ve gathered information, compared options, and narrowed your choices. Now comes the final decision. Use this checklist to ensure you’ve considered everything important before committing to a specific injection molding machine distributor and equipment package.

Technical Requirements:

- ✓ Machine tonnage matches your part’s projected area with 20% safety margin

- ✓ Shot size accommodates your part weight within optimal 20-80% range

- ✓ Injection speed and pressure capability suit your material requirements

- ✓ Temperature control zones provide adequate barrel heating configuration

- ✓ Mold height capacity accepts your tooling dimensions

- ✓ Tie bar spacing allows mold installation and removal

- ✓ Ejection force sufficient for your part geometry and material

Material Compatibility:

- ✓ Screw design appropriate for your primary materials (general purpose, barrier, mixing)

- ✓ Barrel construction handles abrasive or corrosive additives if needed

- ✓ Material drying system capacity matches your hourly consumption

- ✓ Color change procedures minimize contamination for your application

- ✓ Purging compound recommendations available for your material combinations

Automation and Integration:

- ✓ Robot mounting provisions if automation planned now or future

- ✓ Safety door configuration allows robot access

- ✓ Control system I/O capacity supports planned peripheral devices

- ✓ Communication protocols compatible with your factory systems

- ✓ Conveyor integration points available if needed

- ✓ Vision system mounting provisions if quality inspection planned

Quality and Precision:

- ✓ Process control capabilities meet your tolerance requirements

- ✓ Repeatability specifications documented and verified

- ✓ In-mold monitoring options available if needed

- ✓ Data logging capabilities support your quality system

- ✓ Calibration certificates provided for critical sensors and controls

Service and Support:

- ✓ Technical support availability matches your operating schedule

- ✓ Response time commitments defined in writing

- ✓ Spare parts availability and lead times acceptable

- ✓ Emergency service procedures clearly documented

- ✓ Training programs comprehensive and scheduled before startup

- ✓ Process optimization support included or available

- ✓ Remote diagnostic capabilities for faster troubleshooting

Financial Considerations:

- ✓ Total cost of ownership calculated including energy, maintenance, and labor

- ✓ Payment terms align with your cash flow and procurement policies

- ✓ Warranty coverage adequate (typical: 1 year parts and labor)

- ✓ Financing options explored if applicable

- ✓ Resale value expectations reasonable based on brand reputation

- ✓ Insurance requirements reviewed with underwriters

Logistics and Installation:

- ✓ Delivery lead time acceptable for your project schedule

- ✓ Site preparation requirements documented and feasible

- ✓ Rigging and installation plan defined

- ✓ Utility requirements (electrical, water, compressed air) verified

- ✓ Floor loading capacity confirmed adequate

- ✓ Building access dimensions allow machine delivery to intended location

- ✓ Commissioning timeline and responsibility assigned

Regulatory and Safety:

- ✓ Machine meets all applicable safety standards for your region

- ✓ Safety certifications current and documentation provided

- ✓ OSHA or local safety compliance verified

- ✓ Environmental regulations compliance confirmed

- ✓ Noise levels acceptable for your facility

- ✓ Lock-out/tag-out provisions adequate

- ✓ Emergency stop systems properly positioned and functional

If you can check every relevant box, you’ve done thorough due diligence. Any unchecked items need resolution before purchase. Don’t let sales pressure rush you into overlooking critical details. A machine that doesn’t truly fit your needs becomes an expensive mistake that affects production for years.

Start Your Electronics Manufacturing Journey with Daoben Machinery

The electronics industry demands precision, consistency, and reliability from every component. When you’re sourcing injection molding machines for your production needs, the decisions you make today will impact your manufacturing capability for the next 15-20 years. Choosing the right equipment partner isn’t just about buying a machine—it’s about establishing a relationship that supports your growth and evolves with technology.

At Daoben Machinery, we manufacture injection molding equipment from 30 tons to 4000 tons specifically for demanding applications like electronics manufacturing. As a direct manufacturer, we eliminate distributor markup while providing engineering expertise that only comes from designing and building machines ourselves. Our customers benefit from factory-direct pricing, comprehensive technical support, and process optimization assistance that helps them achieve consistent quality and maximum efficiency.

We understand that every application is unique. The machine configuration that works perfectly for smartphone cases requires different specifications than equipment for producing laptop housings or connector components. Our engineering team works with you to specify the exact combination of tonnage, shot size, control system, and automation that matches your specific requirements. We don’t push standard packages—we configure equipment that solves your actual manufacturing challenges.

Our commitment extends far beyond machine delivery. We provide comprehensive operator training, process development support, and ongoing technical assistance. When you have questions or encounter challenges, you speak directly with our engineers—not a sales representative reading from a script. This direct access to manufacturing expertise helps you solve problems quickly and optimize your processes for better quality and efficiency.

Whether you’re establishing a new electronics manufacturing facility, expanding existing capacity, or replacing aging equipment, Daoben Machinery has the experience and capability to support your project. We’ve supplied machines to electronics manufacturers worldwide, and we understand the quality standards, material requirements, and production volumes your industry demands.

Contact us today to discuss your electronics manufacturing requirements. Our engineering team will review your application, recommend appropriate equipment configurations, and provide detailed quotations with complete specifications. As the manufacturer, we control quality, timing, and pricing—giving you the best possible value for your investment.

Don’t settle for working through multiple distributor layers when you can access manufacturer expertise directly. Reach out now to learn how Daoben Machinery can become your partner in precision electronics component manufacturing.